Yes. That uniformity and big amounts of raw woodchip supply cannot be obtained or sourced from heterogeneous natural forests. That would be as cost effective and as easy going as trying to collect a bushel of wheat from a wild prairie instead of from a wheatfield. That is why timber sourced from virgin forests is neither an alternative to nor a substitutive for pulp making tree crops. Fiber crops. Which, in the end, means virgin forests tend to not be harvested for pulp and paper making. And they will be less and less with time, as fiber crops expand to meet the growing demand.

And yes. As time goes by, even if more pulp and paper mills are built to supply an increasing overall amount of pulp and paper products to meet an increasing global demand, each new pulp mill tends to be bigger in capacity, tends to be more ecoefficient and tends to play harder on the cleaner production side. This means that by each produced piece of paper, the number of "hot spots" for pollution risks is lower than ever. And the technologies to prevent and to monitor these risks, better than ever.

Fig. 3: FIBRIA - Jacareí industrial unit Director & Chief Engineer explaining the distribution of the Eucalyptus Pulp & Paper mills and their different parts to visitors from Brazil, the USA, Japan, Finland & Spain.

Once the "Fiber Soup" ends up as cellulosic pulp, it can become market pulp (for export to paper makers) or it can become an intermediate product for paper making in an integrated pulp and paper mill, where market circumstances allow it so.

Fig. 4: Visit to FIBRIA - Jacareí Eucalyptus Paper Mill Control Room, where all the processes are monitorised and adjusted for maximum efficiency. So, The Helm.

These mills are designed to recycle internally as much as possible of the different materials and ingredients, energy and residues, gradually approaching the "as closed cycles as possible" concept. Hence, an every day effort of technique and engineering to reduce the environmental impacts of these bio-refineries processing renewable, recyclable and organic raw materials. A much less impacting environmental footprint already than that one generated by many other industries whose products you and I use every day.

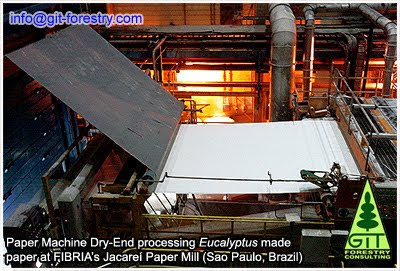

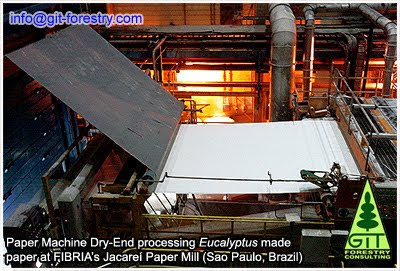

Fig. 5: View of the Paper Machine at FIBRIA - Jacareí Eucalyptus Paper Mill. Eucalyptus cellulosic pulp is transformed into a "spiced fiber soup", pressed, compacted and dried to become large continuous sheets of high quality paper.

High tech bio-refineries, refining cellulose from Eucalyptus wood chips, and making recyclable paper from cellulose. There is even an increasing tendency to use biological aid for certain processes, which is a form of organic industrial operation!

Fig. 6: View of the raw product: high quality Eucalyptus fiber-made paper in a large neverending sheet, to be later rolled, or cut to length.

Nothing more and nothing else than 200 years of technological evolution applied to the same basic Fourdrinier Paper Machine design once invented by Louis-Nicolas Robert and 130 years of technological evolution applied to the same basic Kraft Process for wood pulp making developed by Carl Dahl .

Fig. 7: A view of FIBRIA - Jacareí Eucalyptus Paper Mill Finishing Room, where dry Eucalyptus paper is processed, cut to length and packaged for storage and immediate distribution.

In the end, those Eucalyptus wood fibres end up becoming a thin layer of fine quality paper, produced and marketed at a fraction of a cost and in extraordinarily larger amounts of what paper used to be when it was a luxury at hand of very few. An affordable commodity reaching the largest number of people with highest average literacy rate in human history.

Fig. 8: A summary of the Eucalyptus Pulp & Paper production process at FIBRIA, depicting all the way from an Eucalyptus urograndis log piece (bottom, left), passing by wood chips, unbleached pulp, bleached pulp and pulp bales (bottom right) ... to a wide range of high quality papers, for printing, hygiene or packaging.

Eucalyptus paper is around you and me every day. It can take many different outlooks, and we do not even notice it is there, at our homes or pockets as tissue paper, at our local supermarkets as cardboard or packaging paper in countless variations, as part of the magazines and books we read for leisure or to increase our knowledge.

It is sourced from a day by day more sustainable forestry resource based on one of the most efficient trees in the world, produced on a tiny fraction of available land, but supplying a vast amount of our needs of industrial timber, for products like these, but for many others too.

It can easily reach your desk. As printing paper at a reasonable cost. In as many variations as your specific needs.

It is your responsibility to decide what to use it for, in what amounts and with what priority. It is also your responsibility to find out the best way to put the fibers on your used paper back into the system through recycling.

But one thing is certain: Eucalyptus printing paper at your desk is an example of a recyclable product, increasingly manufactured under sustainability principles using ever improving technologies to avoid environmental impacts as much as feasible, sourced from renewable organic bio-materials produced by planted trees that filter waters, clean up the air, counterbalance the dangers of deforestation caused by our ever increasing demand of food, act as carbon sinks helping the mitigation of the dangers of climate change and relieve pressure on virgin forests for the procurement of timber resources, for this and other final products we also use everyday. Use them wisely.

Acknowledgements

Want to contact us?

Contact GIT Forestry Consulting - Eucalyptologics

GIT's Eucalyptology Topics

© 2007-2009 Gustavo Iglesias Trabado. Please contact us if you want to use all or part of this text and photography elsewhere. We like to share, but we do not like rudeness.

Eucalyptus Online Book & Newsletter

by Celso Foelkel - Celsius Degree

Eucalyptus Online Book & Newsletter

by Celso Foelkel - Celsius Degree

Eco-efficient Pulp Mills - By Celso Foelkel - Celsius Degree

Eco-efficient Pulp Mills - By Celso Foelkel - Celsius Degree

PinusLetter - By Ester Foelkel - Celsius Degree

PinusLetter - By Ester Foelkel - Celsius Degree